PIR Motion Sensor

——

——

——

——

——

——

PIR Motion Sensor

Passive infrared (PIR) sensors are motion-detecting devices used in security systems across the world, even though you may not see them, they probably see you.

This is a simple to use motion sensor. Power it up and wait 1-2 seconds for the sensor to get a snapshot of the still room. If anything moves after that period, the ‘alarm’ pin will go low.

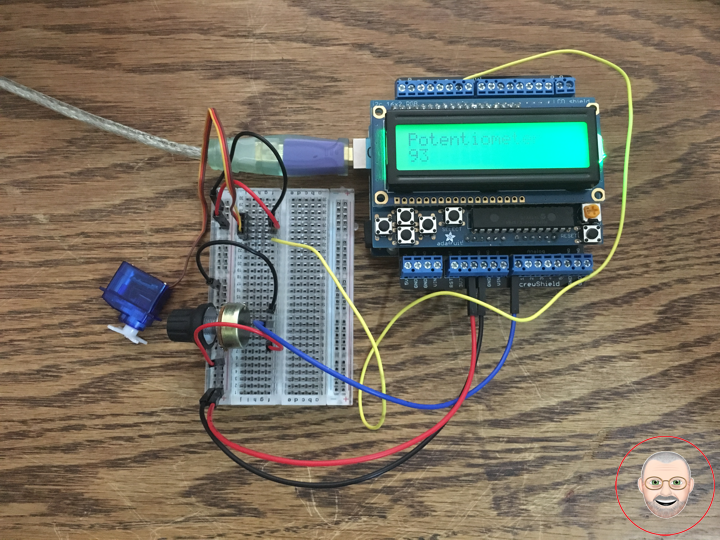

Pololu Adjustable Boost Regulator 2.5-9.5V

This powerful, adjustable boost regulator can generate an output voltage as high as 9.5 V from an input voltage as low as 1.5 V, all in a compact, 0.42″ x 0.88″ x 0.23″ package. A trimmer potentiometer lets you set the boost regulator’s output voltage to a value between 2.5 and 9.5 V.

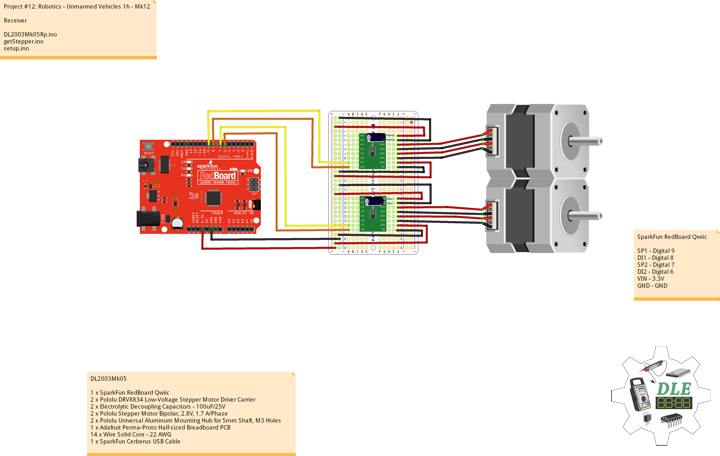

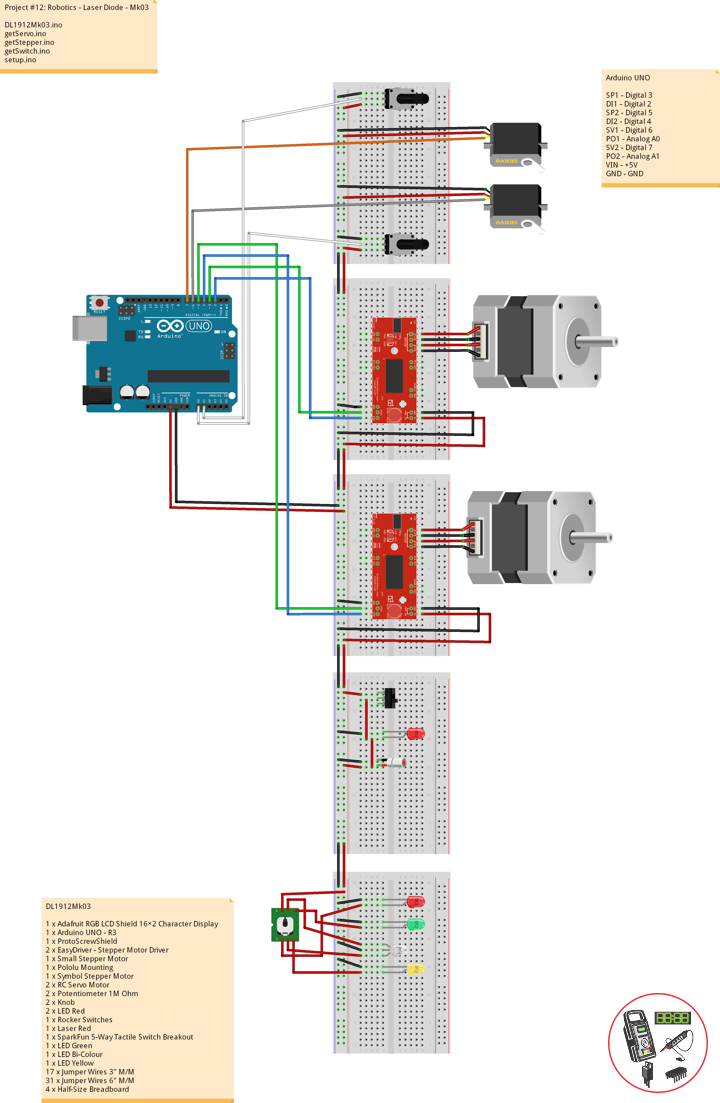

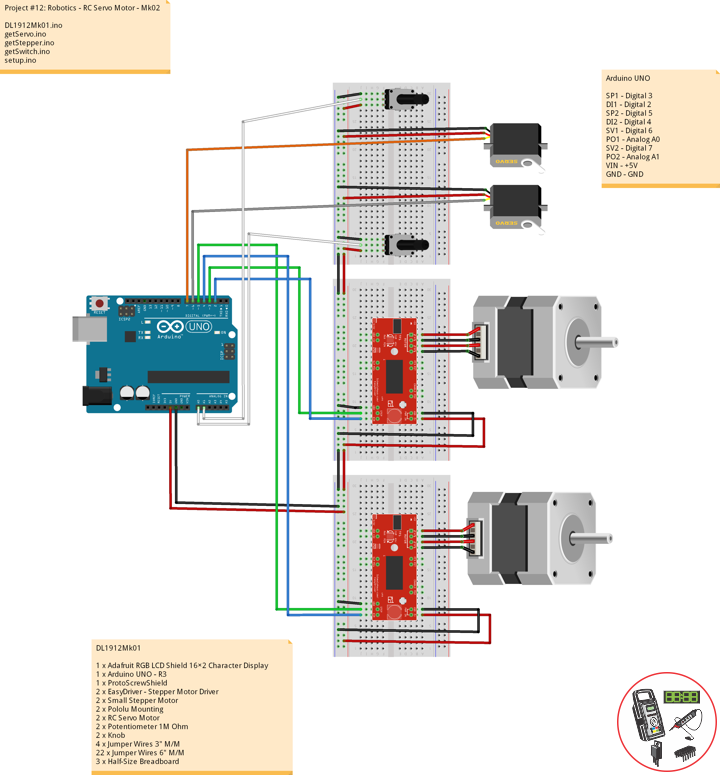

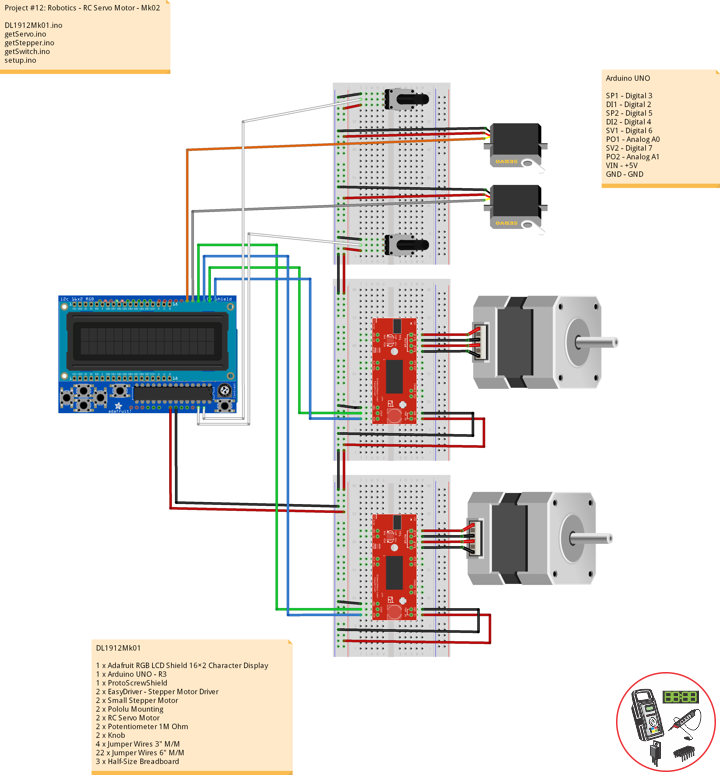

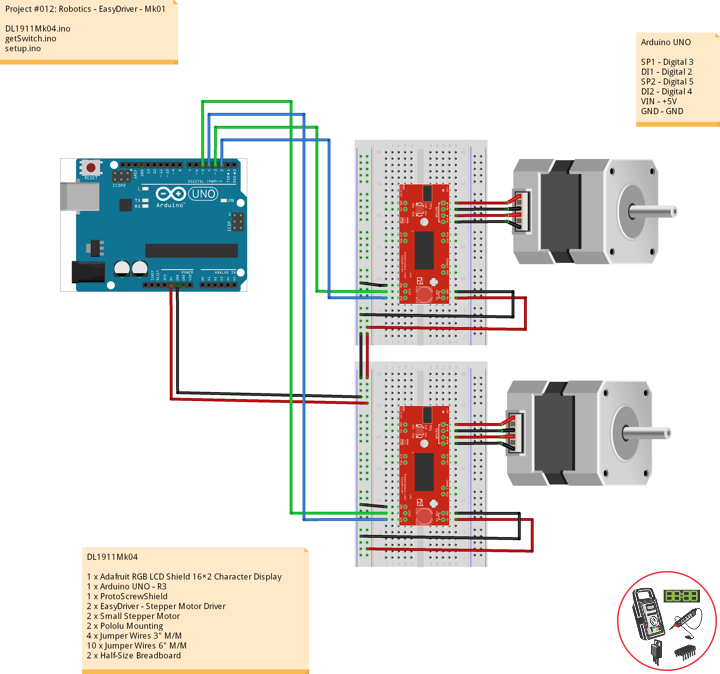

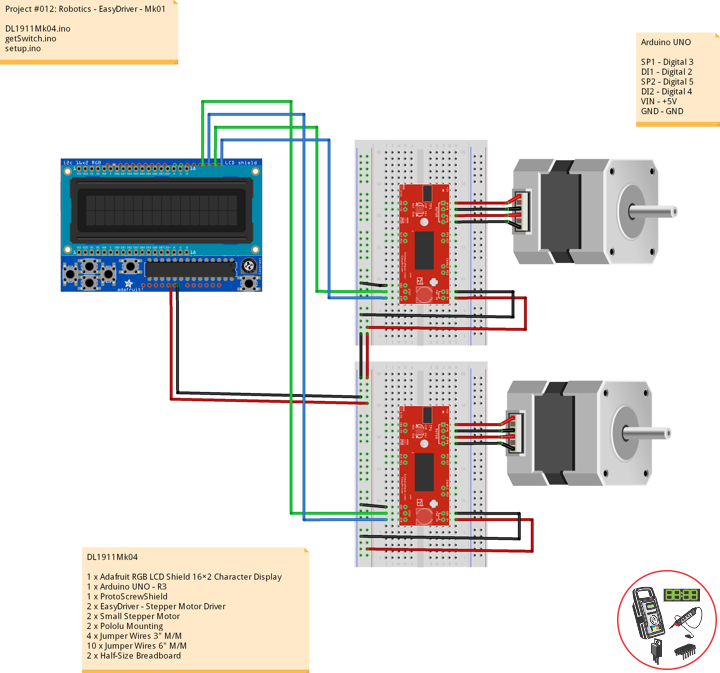

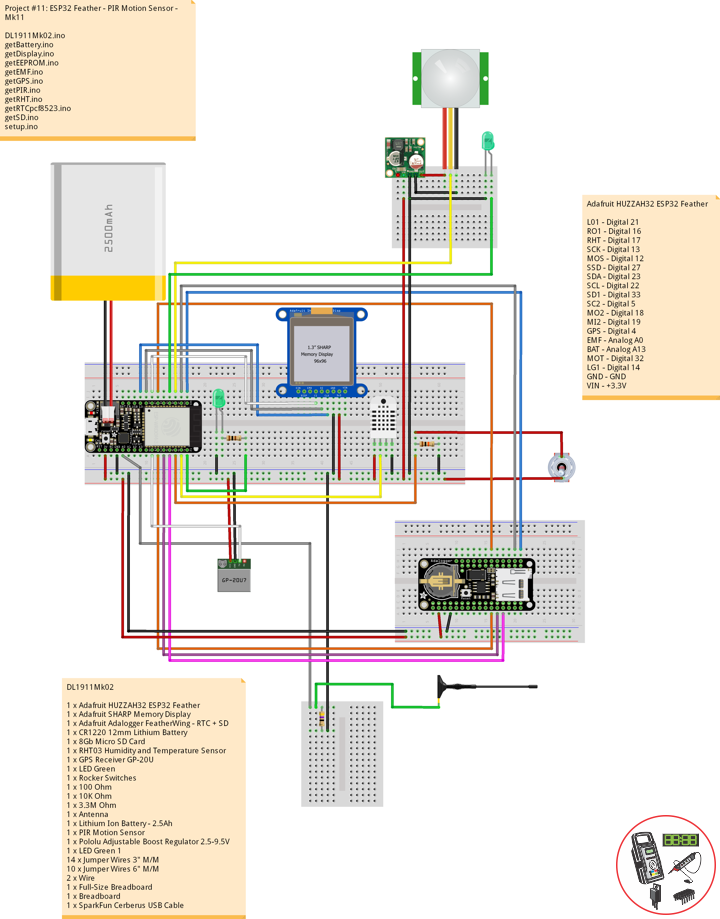

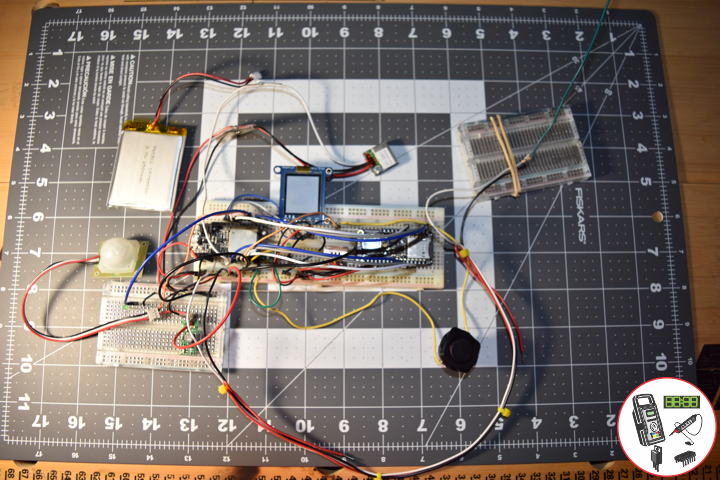

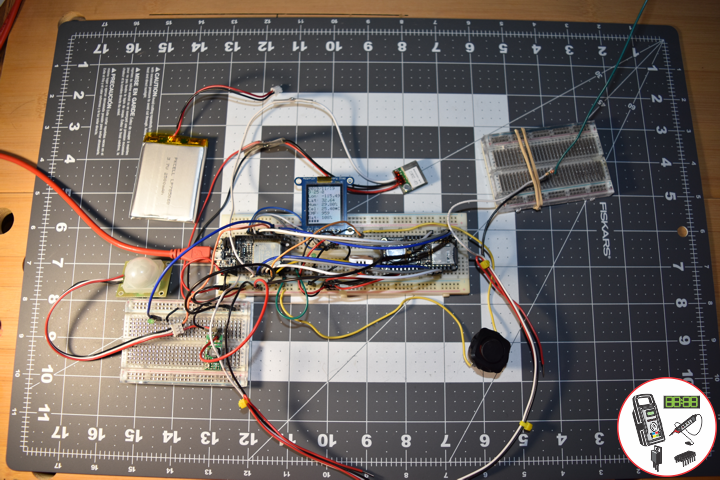

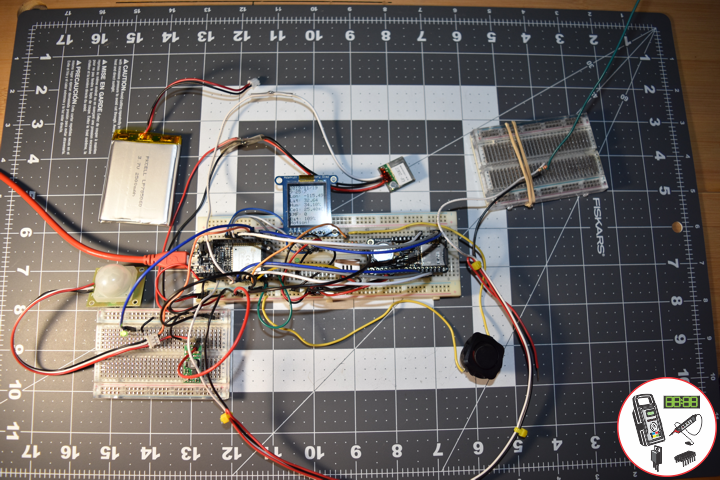

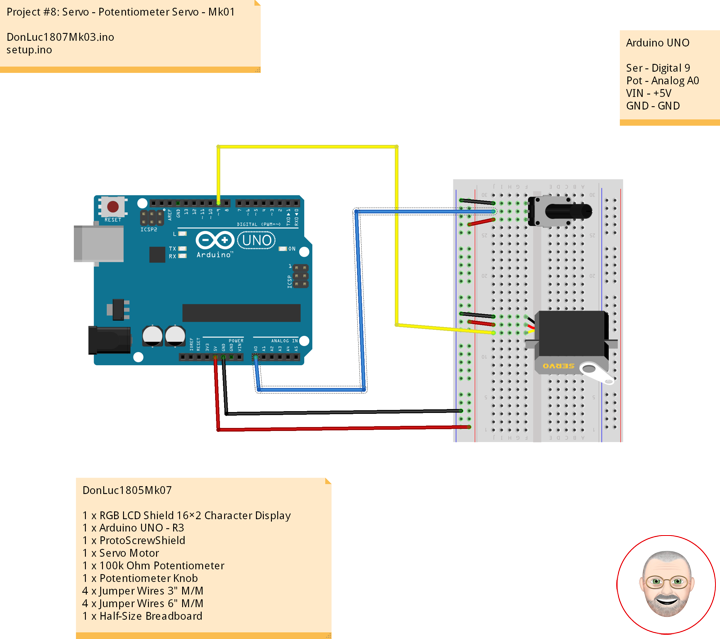

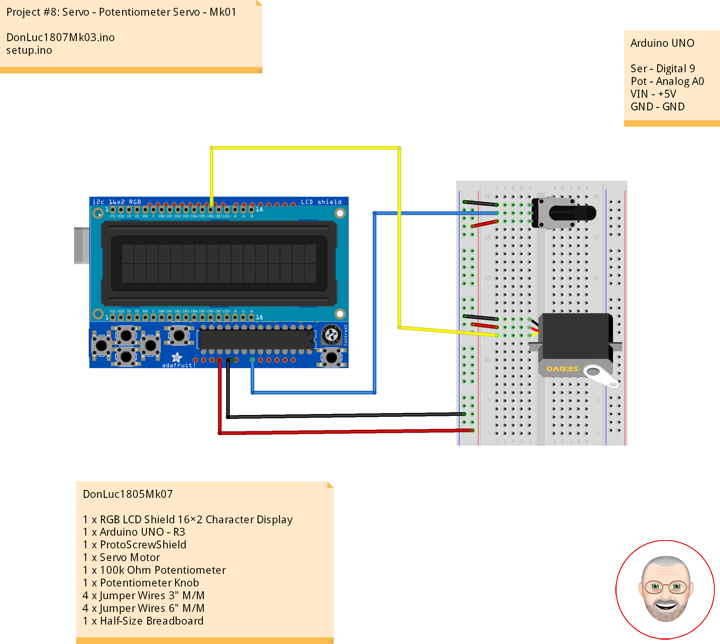

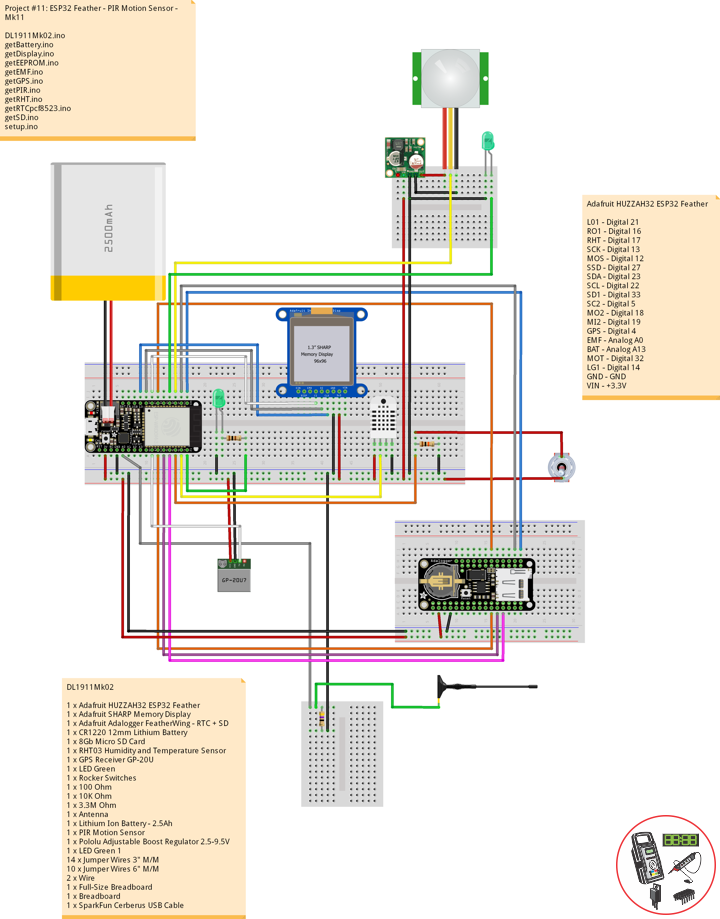

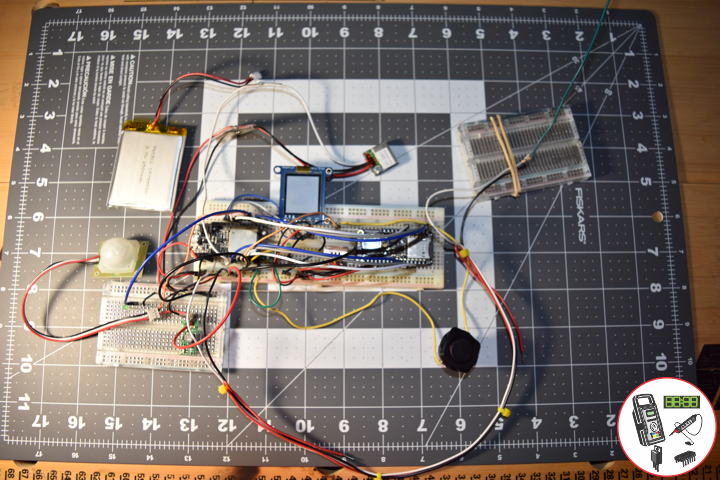

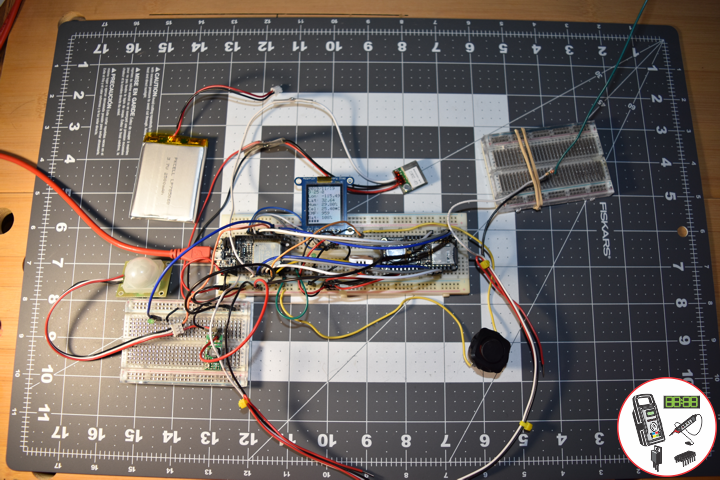

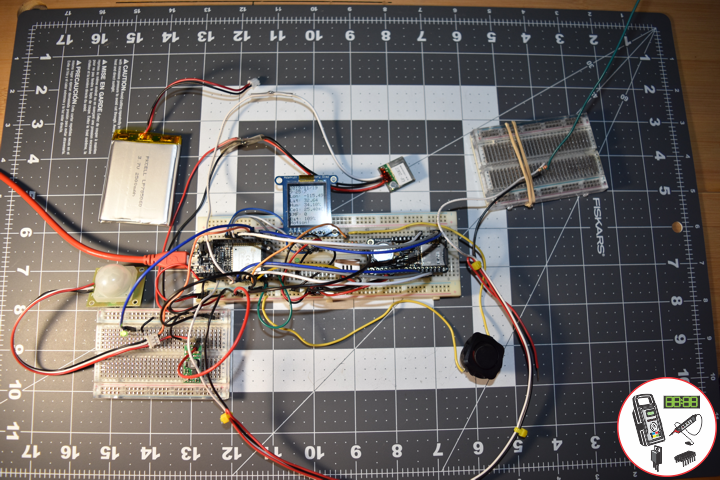

DL1911Mk02

1 x Adafruit HUZZAH32 ESP32 Feather

1 x Adafruit SHARP Memory Display

1 x Adafruit Adalogger FeatherWing – RTC + SD

1 x CR1220 12mm Lithium Battery

1 x 8Gb Micro SD Card

1 x RHT03 Humidity and Temperature Sensor

1 x GPS Receiver GP-20U

1 x LED Green

1 x Rocker Switches

1 x 100 Ohm

1 x 10K Ohm

1 x 3.3M Ohm

1 x Antenna

1 x Lithium Ion Battery – 2.5Ah

1 x PIR Motion Sensor

1 x Pololu Adjustable Boost Regulator 2.5-9.5V

1 x LED Green 1

14 x Jumper Wires 3″ M/M

10 x Jumper Wires 6″ M/M

2 x Wire

1 x Full-Size Breadboard

2 x Breadboard

1 x SparkFun Cerberus USB Cable

Adafruit HUZZAH32 ESP32 Feather

LG0 – Digital 21

RO1 – Digital 16

RHT – Digital 17

SCK – Digital 13

MOS – Digital 12

SSD – Digital 27

SDA – Digital 23

SCL – Digital 22

SD1 – Digital 33

SC2 – Digital 5

MO2 – Digital 18

MI2 – Digital 19

GPS – Digital 4

EMF – Analog A0

BAT – Analog A13

MOT – Digital 32

LG1 – Digital 14

GND – GND

VIN – +3.3V

DL1911Mk02.ino

// ***** Don Luc Electronics *****

// Software Version Information

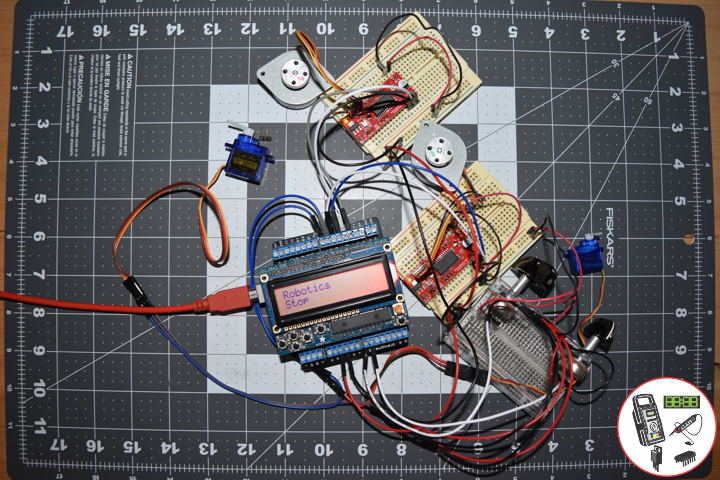

// Project #11: HUZZAH32 ESP32 Feather - PIR Motion - Mk11

// 11-02

// DL1911Mk02p.ino 11-11

// Adafruit HUZZAH32 ESP32 Feather Board

// SHARP Display

// LED Green

// Adalogger FeatherWing - RTC + SD

// EEPROM

// RHT03 Humidity and Temperature Sensor

// Rocker Switches

// GPS Receiver

// EMF Meter (Single Axis)

// Lithium Ion Battery - 2.5Ah

// PIR Motion

// Pololu Adjustable Boost Regulator 2.5-9.5V

// LED Green 1

// include Library Code

// SHARP Memory Display

#include <Adafruit_SharpMem.h>

#include <Adafruit_GFX.h>

// Date and Time

#include "RTClib.h"

// EEPROM library to read EEPROM with unique ID for unit

#include "EEPROM.h"

// RHT Humidity and Temperature Sensor

#include <SparkFun_RHT03.h>

// SD Card

#include "FS.h"

#include "SD.h"

#include "SPI.h"

// GPS Receiver

#include <TinyGPS++.h>

#include <HardwareSerial.h>

// SHARP Memory Display

// any pins can be used

#define SHARP_SCK 13

#define SHARP_MOSI 12

#define SHARP_SS 27

// Set the size of the display here, e.g. 144x168!

Adafruit_SharpMem display(SHARP_SCK, SHARP_MOSI, SHARP_SS, 144, 168);

// The currently-available SHARP Memory Display (144x168 pixels)

// requires > 4K of microcontroller RAM; it WILL NOT WORK on Arduino Uno

// or other <4K "classic" devices!

#define BLACK 0

#define WHITE 1

int minorHalfSize; // 1/2 of lesser of display width or height

// LED Green

int iLEDGreen = 21; // LED Green

// PCF8523 Precision RTC

RTC_PCF8523 rtc;

String dateRTC = "";

String timeRTC = "";

// RHT Humidity and Temperature Sensor

const int RHT03_DATA_PIN = 17; // RHT03 data pin Digital 17

RHT03 rht; // This creates a RTH03 object, which we'll use to interact with the sensor

float latestHumidity;

float latestTempC;

float latestTempF;

// SD Card

const int chipSelect = 33; // SD Card

String zzzzzz = "";

// Rocker Switches

int iRow1 = 16; // Rocker Switches Digital 16

int iRow1State = 0; // Variable for reading the pushbutton status

// ESP32 HardwareSerial

HardwareSerial tGPS(2);

// GPS Receiver

#define gpsRXPIN 4

#define gpsTXPIN 36 // This one is unused and doesnt have a conection

// The TinyGPS++ object

TinyGPSPlus gps;

float TargetLat;

float TargetLon;

int Status = 0;

// EMF Meter (Single Axis)

#define NUMREADINGS 15 // Raise this number to increase data smoothing

int senseLimit = 15; // Raise this number to decrease sensitivity (up to 1023 max)

int val = 0; // Val

int iEMF = A0; // EMF Meter

int readings[ NUMREADINGS ]; // Readings from the analog input

int ind = 0; // Index of the current reading

int total = 0; // Running total

int average = 0; // Final average of the probe reading

int iEMFDis = 0;

int iEMFRect = 0;

// LiPo Battery

const int bat = A13; // LiPo Battery

uint16_t vbat = 0;

int iBat = 0;

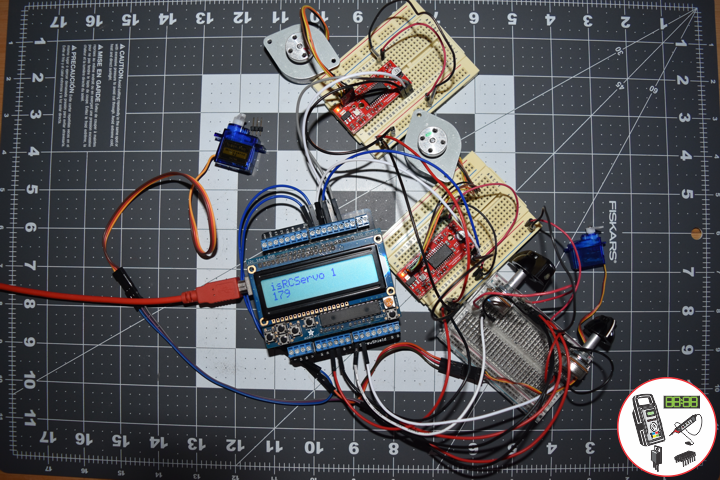

// PIR Motion

const int iMotion = 32; // Motion detector

const int iLEDGreen1 = 14; // LED Green 1

int proximity = LOW; // Proximity

String Det = "";

// The current address in the EEPROM (i.e. which byte

// we're going to read to next)

#define EEPROM_SIZE 64

String sver = "11-2.p";

// Unit ID information

String uid = "";

void loop() {

// Receives NEMA data from GPS receiver

// This sketch displays information every time a new sentence is correctly encoded.

while ( tGPS.available() > 0)

if (gps.encode( tGPS.read() ))

{

displayInfo();

}

if (millis() > 5000 && gps.charsProcessed() < 10)

{

while(true);

}

// Date and Time

isRTC();

// RHT03 Humidity and Temperature Sensor

isRHT03();

// SHARP Memory Display On

isDisplayOn();

// Rocker Switched

// Read the state of the iRow1 value

iRow1State = digitalRead(iRow1);

// EMF Meter (Single Axis)

isEMF();

// LiPo Battery

isBattery();

// isPIR Motion

isPIR();

// Check if the pushbutton is pressed. If it is, the buttonState is HIGH:

if (iRow1State == HIGH) {

// iLEDGreen

digitalWrite(iLEDGreen, HIGH );

// SD Card

isSD();

} else {

// iLEDGreen

digitalWrite(iLEDGreen, LOW );

}

// Delay

delay( 1000 );

}

getBattery.ino

// LiPo Battery

void isBattery() {

// Battery

vbat = analogRead(bat);

vbat = vbat / 2;

iBat = map( vbat, 1, 1064, 1, 100);

}

getDisplay.ino

// SHARP Memory Display On

void isDisplayOn() {

// Clear Display

display.clearDisplay();

// Text display date, time, LED on, Etc...

display.setRotation(4);

display.setTextSize(2);

display.setTextColor(BLACK);

// Date

display.setCursor(0,1);

display.println( dateRTC );

// Time

display.setCursor(0,17);

display.println( timeRTC );

// Longitude

display.setCursor(0,35);

display.print("Lon: ");

display.println( TargetLon );

// Latitude

display.setCursor(0,55);

display.print("Lat: ");

display.println( TargetLat );

// Humidity

display.setCursor(0,74);

display.print("Hum: ");

display.print( latestHumidity );

display.println("%");

// Temp C

display.setCursor(0,94);

display.print("Cel: ");

display.print( latestTempC );

display.println("*C");

// EMF Meter

display.setCursor(0,114);

display.print("EMF: ");

display.println( iEMFDis );

// Battery

display.setCursor(0,134);

display.print("Bat: ");

display.print( iBat );

display.println( "%" );

// PIR Motion

display.println( Det );

display.setCursor(0,154);

// Refresh

display.refresh();

}

// SHARP Memory Display - UID

void isDisplayUID() {

// Clear Display

display.clearDisplay();

// text display EEPROM

display.setRotation(4);

display.setTextSize(2);

display.setTextColor(BLACK);

// EEPROM with Unique ID

display.setCursor(0,20);

display.print( "UID: " );

display.println( uid );

// Version

display.setCursor(0,45);

display.print( "VER: ");

display.println( sver );

// Refresh

display.refresh();

delay( 100 );

}

getEEPROM.ino

// EEPROM

void GetUID()

{

// Get unit ID

uid = "";

for (int x = 0; x < 5; x++)

{

uid = uid + char(EEPROM.read(x));

}

}

getEMF.ino

// EMF Meter (Single Axis)

// setupEMF

void setupEMF() {

// EMF Meter (Single Axis)

pinMode( iEMF, OUTPUT ); // EMF Meter

for (int i = 0; i < NUMREADINGS; i++){

readings[ i ] = 0; // Initialize all the readings to 0

}

}

// isEMF

void isEMF(){

// Probe

val = analogRead( iEMF ); // Take a reading from the probe

if( val >= 1 ){ // If the reading isn't zero, proceed

val = constrain( val, 1, senseLimit ); // Turn any reading higher than the senseLimit value into the senseLimit value

val = map( val, 1, senseLimit, 1, 1023 ); // Remap the constrained value within a 1 to 1023 range

total -= readings[ ind ]; // Subtract the last reading

readings[ ind ] = val; // Read from the sensor

total += readings[ ind ]; // Add the reading to the total

ind = ( ind + 1 ); // Advance to the next index

if ( ind >= NUMREADINGS ) { // If we're at the end of the array...

ind = 0; // ...wrap around to the beginning

}

average = total / NUMREADINGS; // Calculate the average

// average = val;

}

else

{

iEMFRect = 0;

val = 0;

average = 0;

}

iEMFDis = average;

iEMFRect = map( average, 1, 1023, 1, 144 );

}

getGPS.ino

// GPS Receiver

void setupGPS() {

// Setup GPS

tGPS.begin( 9600 , SERIAL_8N1, gpsRXPIN, gpsTXPIN );

}

// GPS Vector Pointer Target

void displayInfo()

{

// Location

if (gps.location.isValid())

{

TargetLat = gps.location.lat();

TargetLon = gps.location.lng();

Status = 2;

}

else

{

Status = 0;

}

}

getPIR.ino

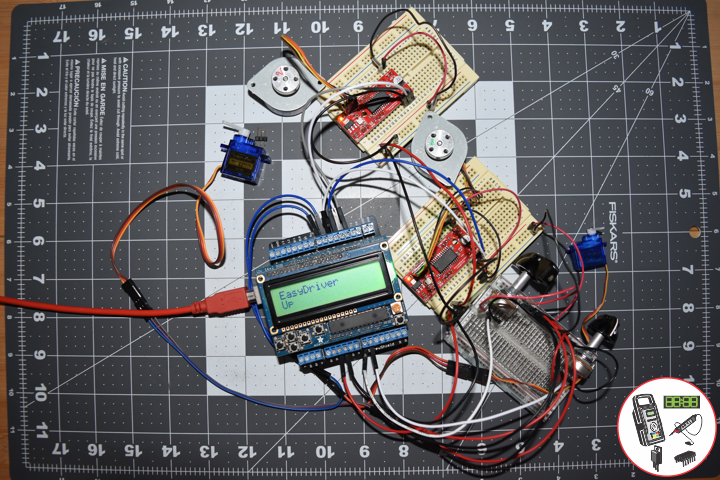

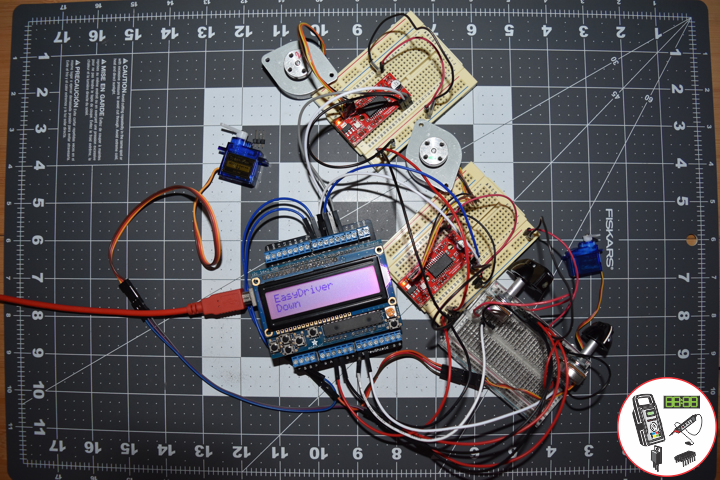

// PIR Motion

void setupPIR() {

// Setup PIR Montion

pinMode(iMotion, INPUT_PULLUP);

pinMode(iLEDGreen1, OUTPUT);

}

// isPIR Motion

void isPIR() {

// Proximity

proximity = digitalRead(iMotion);

if (proximity == LOW)

{

// PIR Motion Sensor's LOW, Motion is detected

// LED Green 1 - HIGH

digitalWrite(iLEDGreen1, HIGH);

Det = "Motion!";

}

else

{

// PIR Motion Sensor's HIGH

// LED Green 1 - LOW

digitalWrite(iLEDGreen1, LOW);

Det = "****";

}

}

getRHT.ino

// RHT03 Humidity and Temperature Sensor

void isRHT03(){

// Call rht.update() to get new humidity and temperature values from the sensor.

int updateRet = rht.update();

// The humidity(), tempC(), and tempF() functions can be called -- after

// a successful update() -- to get the last humidity and temperature value

latestHumidity = rht.humidity();

latestTempC = rht.tempC();

latestTempF = rht.tempF();

}

getRTCpcf8523.ino

// PCF8523 Precision RTC

void setupRTC() {

// pcf8523 Precision RTC

if (! rtc.begin()) {

while (1);

}

if (! rtc.initialized()) {

// Following line sets the RTC to the date & time this sketch was compiled

rtc.adjust(DateTime(F(__DATE__), F(__TIME__)));

// This line sets the RTC with an explicit date & time, for example to set

// January 21, 2014 at 3am you would call:

// rtc.adjust(DateTime(2018, 9, 29, 12, 17, 0));

}

}

// Date and Time RTC

void isRTC () {

// Date and Time

DateTime now = rtc.now();

// Date

dateRTC = now.year(), DEC;

dateRTC = dateRTC + "/";

dateRTC = dateRTC + now.month(), DEC;

dateRTC = dateRTC + "/";

dateRTC = dateRTC + now.day(), DEC;

// Time

timeRTC = now.hour(), DEC;

timeRTC = timeRTC + ":";

timeRTC = timeRTC + now.minute(), DEC;

timeRTC = timeRTC + ":";

timeRTC = timeRTC + now.second(), DEC;

}

getSD.ino

// SD Card

void setupSD() {

// SD Card

pinMode( chipSelect , OUTPUT );

if(!SD.begin( chipSelect )){

;

return;

}

uint8_t cardType = SD.cardType();

if(cardType == CARD_NONE){

;

return;

}

//Serial.print("SD Card Type: ");

if(cardType == CARD_MMC){

;

} else if(cardType == CARD_SD){

;

} else if(cardType == CARD_SDHC){

;

} else {

;

}

uint64_t cardSize = SD.cardSize() / (1024 * 1024);

}

// SD Card

void isSD() {

zzzzzz = "";

zzzzzz = uid + "|" + sver + "|" + dateRTC + "|" + timeRTC + "|" + Status + "|" + TargetLon + "|" + TargetLat + "|" + latestHumidity + "|" + latestTempC + "|" + latestTempF + "|" + average + "|" + iBat + "|" + Det + "|\r";

char msg[zzzzzz.length() + 1];

zzzzzz.toCharArray(msg, zzzzzz.length() + 1);

appendFile(SD, "/espdata.txt", msg );

}

// List Dir

void listDir(fs::FS &fs, const char * dirname, uint8_t levels){

dirname;

File root = fs.open(dirname);

if(!root){

return;

}

if(!root.isDirectory()){

return;

}

File file = root.openNextFile();

while(file){

if(file.isDirectory()){

file.name();

if(levels){

listDir(fs, file.name(), levels -1);

}

} else {

file.name();

file.size();

}

file = root.openNextFile();

}

}

// Write File

void writeFile(fs::FS &fs, const char * path, const char * message){

path;

File file = fs.open(path, FILE_WRITE);

if(!file){

return;

}

if(file.print(message)){

;

} else {

;

}

file.close();

}

// Append File

void appendFile(fs::FS &fs, const char * path, const char * message){

//Serial.printf("Appending to file: %s\n", path);

path;

File file = fs.open(path, FILE_APPEND);

if(!file){

return;

}

if(file.print(message)){

;

} else {

;

}

file.close();

}

setup.ino

// Setup

void setup() {

// EEPROM with Unique ID

EEPROM.begin(EEPROM_SIZE);

// Get Unit ID

GetUID();

// GPS Receiver

// Setup GPS

setupGPS();

// SHARP Display start & clear the display

display.begin();

display.clearDisplay();

isDisplayUID();

delay( 5000 );

// Initialize the LED Green

pinMode(iLEDGreen, OUTPUT);

// PCF8523 Precision RTC

setupRTC();

// Date and Time RTC

isRTC();

// RHT03 Humidity and Temperature Sensor

// Call rht.begin() to initialize the sensor and our data pin

rht.begin(RHT03_DATA_PIN);

// SD Card

setupSD();

// Rocker Switches

pinMode(iRow1, INPUT);

// EMF Meter (Single Axis)

setupEMF();

// PIR Motion

setupPIR();

}

Follow Us

Web: https://www.donluc.com/

Web: http://neosteamlabs.com/

Web: http://www.jlpconsultants.com/

YouTube: https://www.youtube.com/channel/UC5eRjrGn1CqkkGfZy0jxEdA

Facebook: https://www.facebook.com/neosteam.labs.9/

Instagram: https://www.instagram.com/neosteamlabs/

Pinterest: https://www.pinterest.com/NeoSteamLabs/

Twitter: https://twitter.com/labs_steam

Etsy: https://www.etsy.com/shop/NeoSteamLabs