——

——

——

——

——

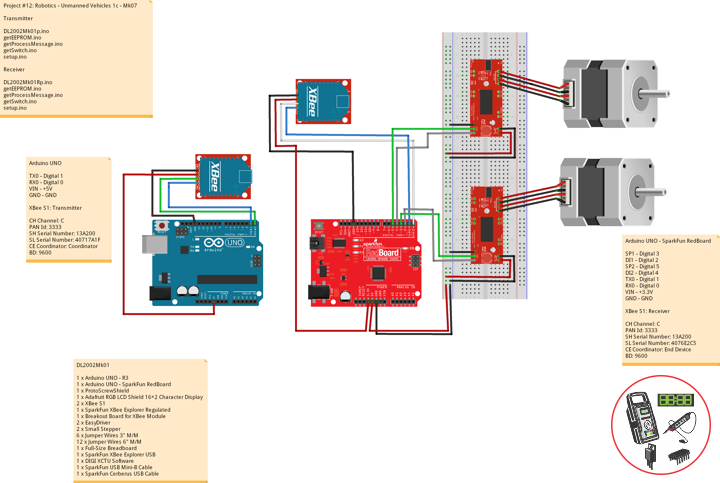

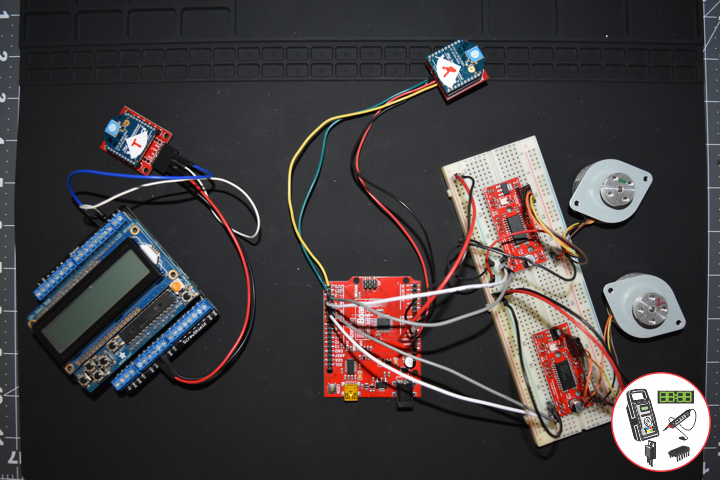

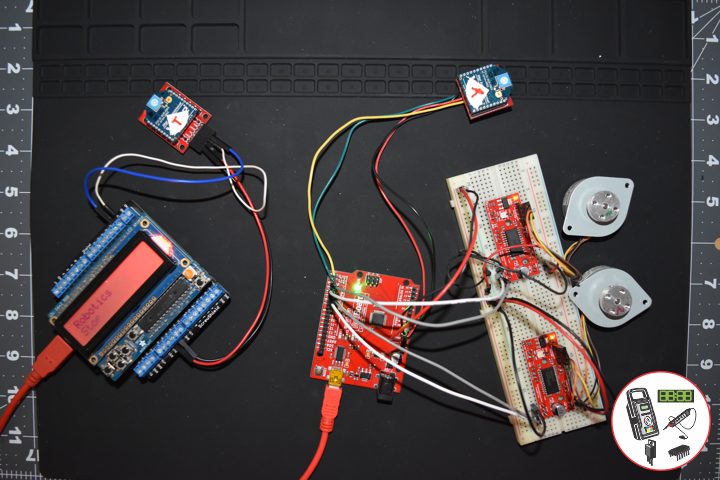

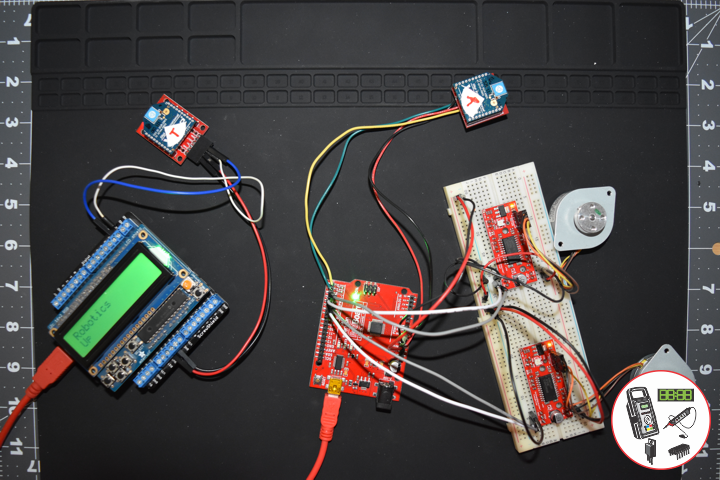

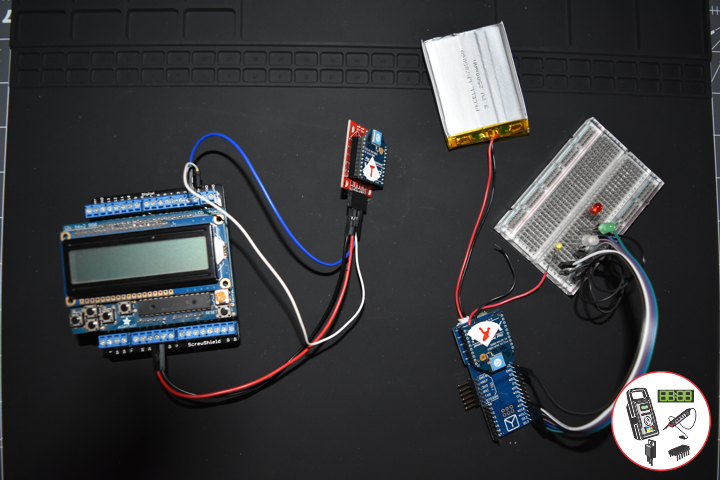

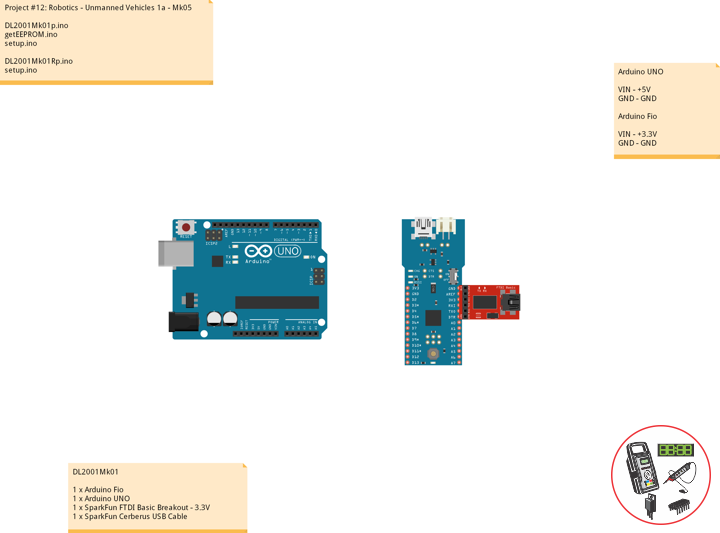

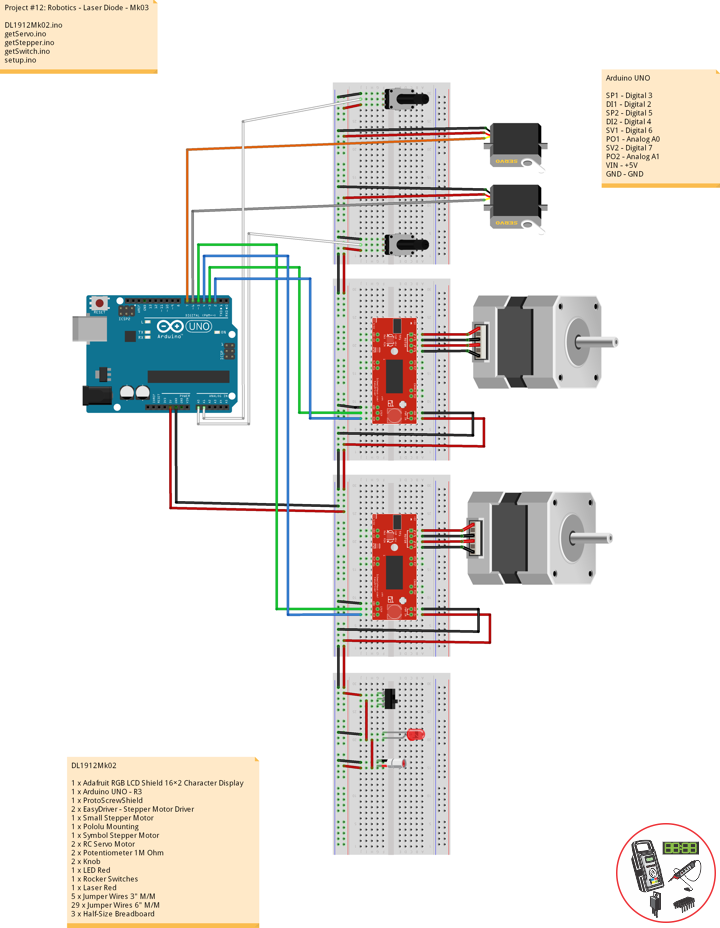

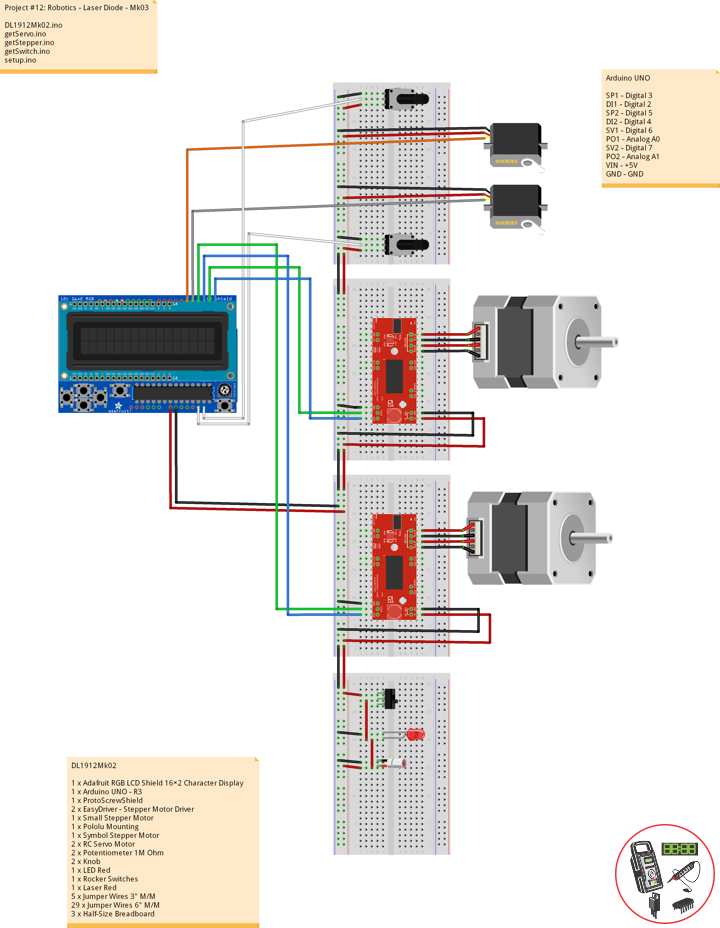

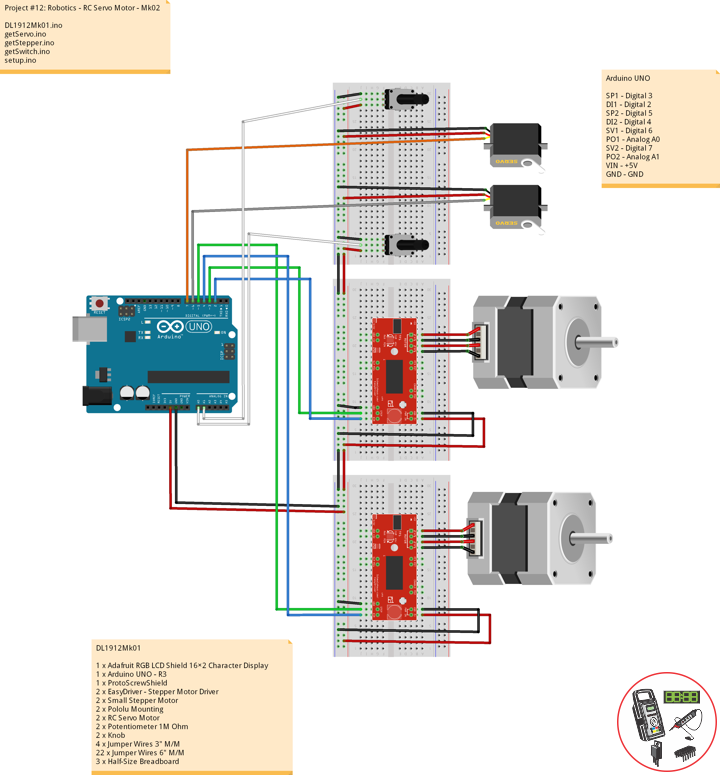

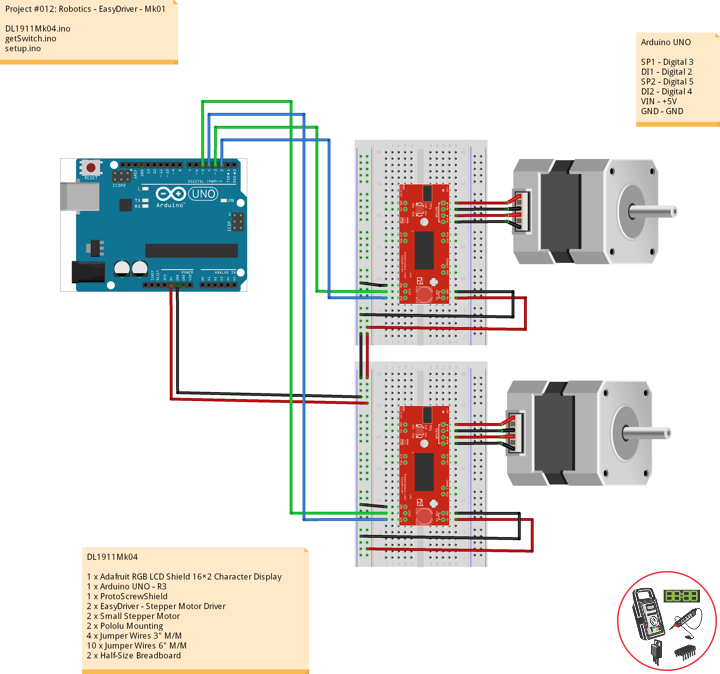

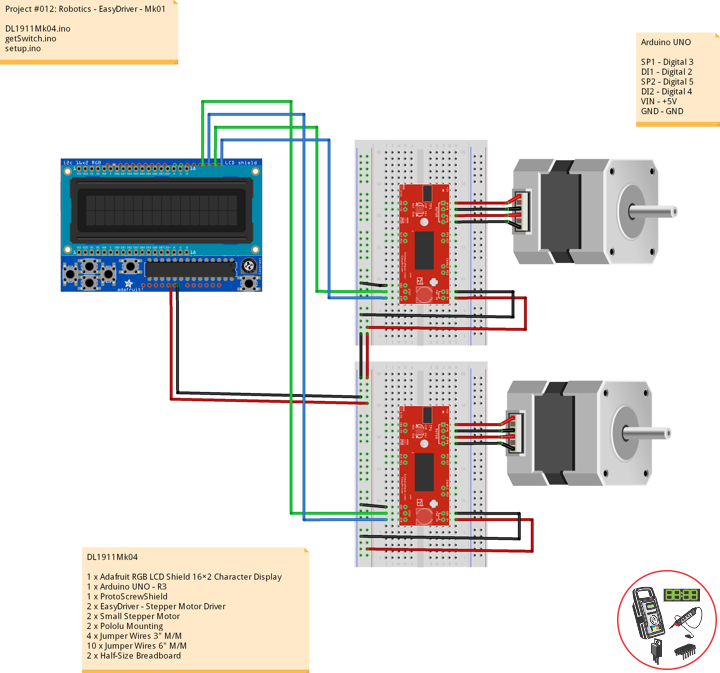

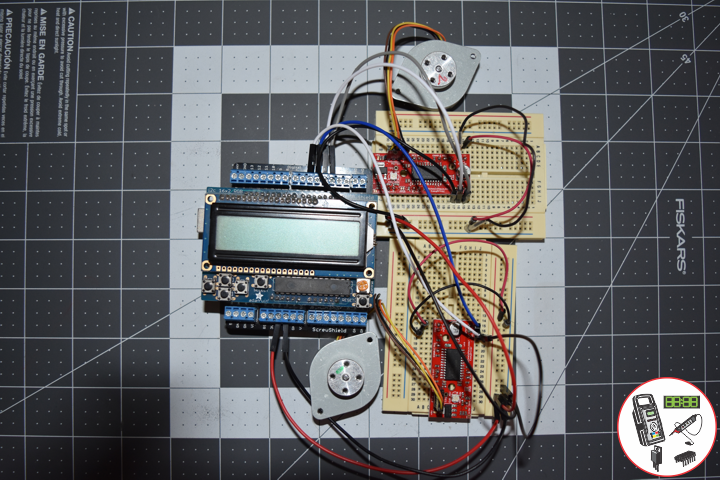

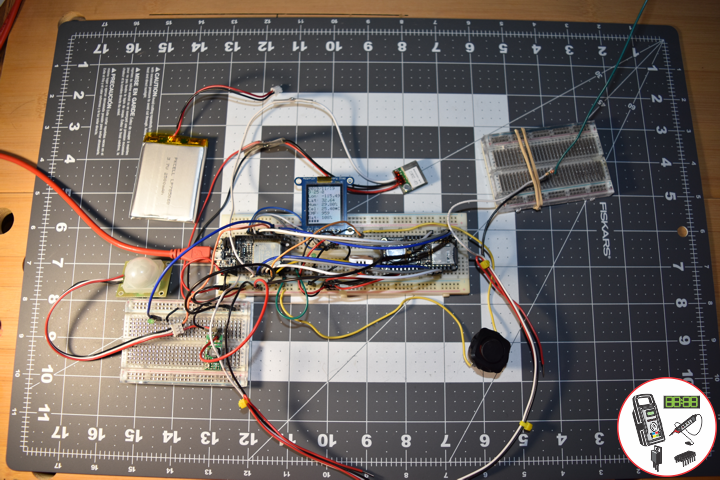

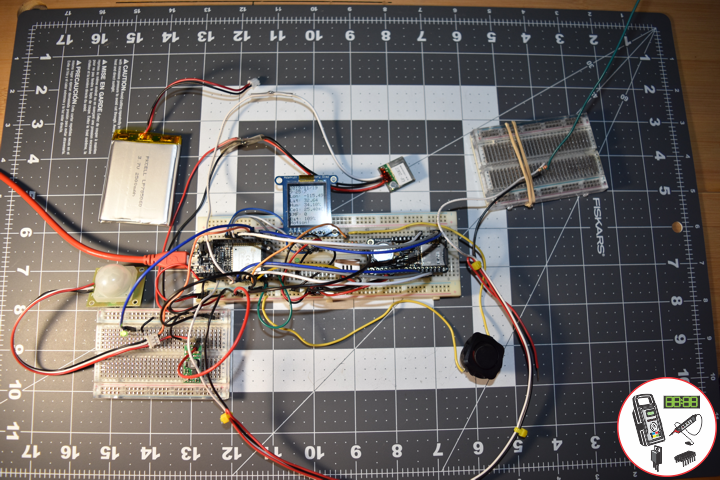

DL2002Mk01

1 x Arduino UNO – R3

1 x Arduino UNO – SparkFun RedBoard

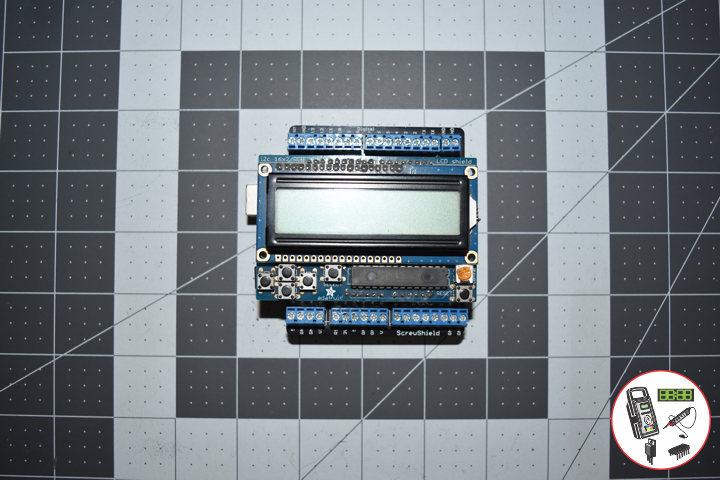

1 x ProtoScrewShield

1 x Adafruit RGB LCD Shield 16×2 Character Display

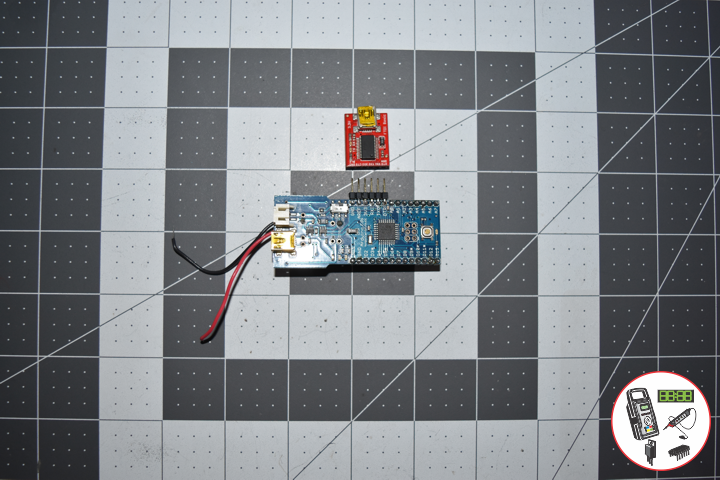

2 x XBee S1

1 x SparkFun XBee Explorer Regulated

1 x Breakout Board for XBee Module

2 x EasyDriver

2 x Small Stepper

6 x Jumper Wires 3″ M/M

12 x Jumper Wires 6″ M/M

1 x Full-Size Breadboard

1 x SparkFun XBee Explorer USB

1 x DIGI XCTU Software

1 x SparkFun USB Mini-B Cable

1 x SparkFun Cerberus USB Cable

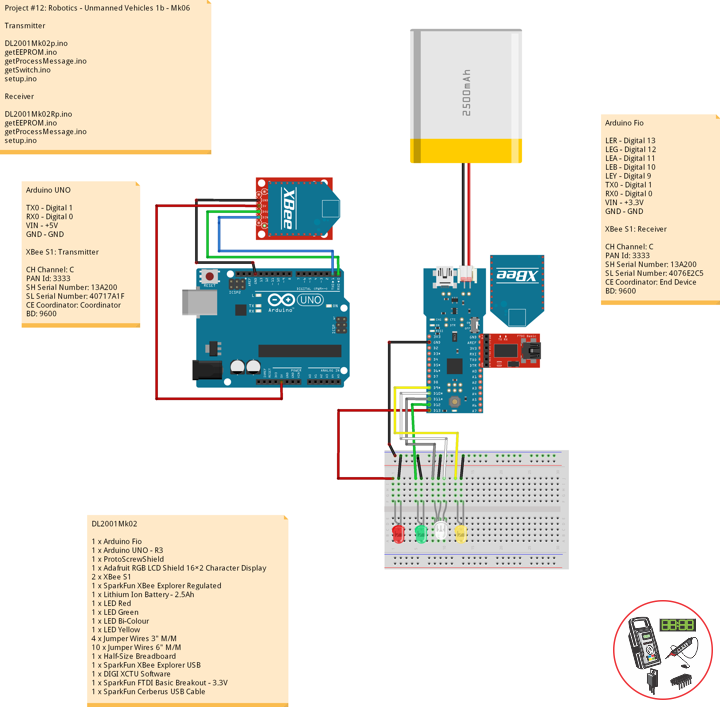

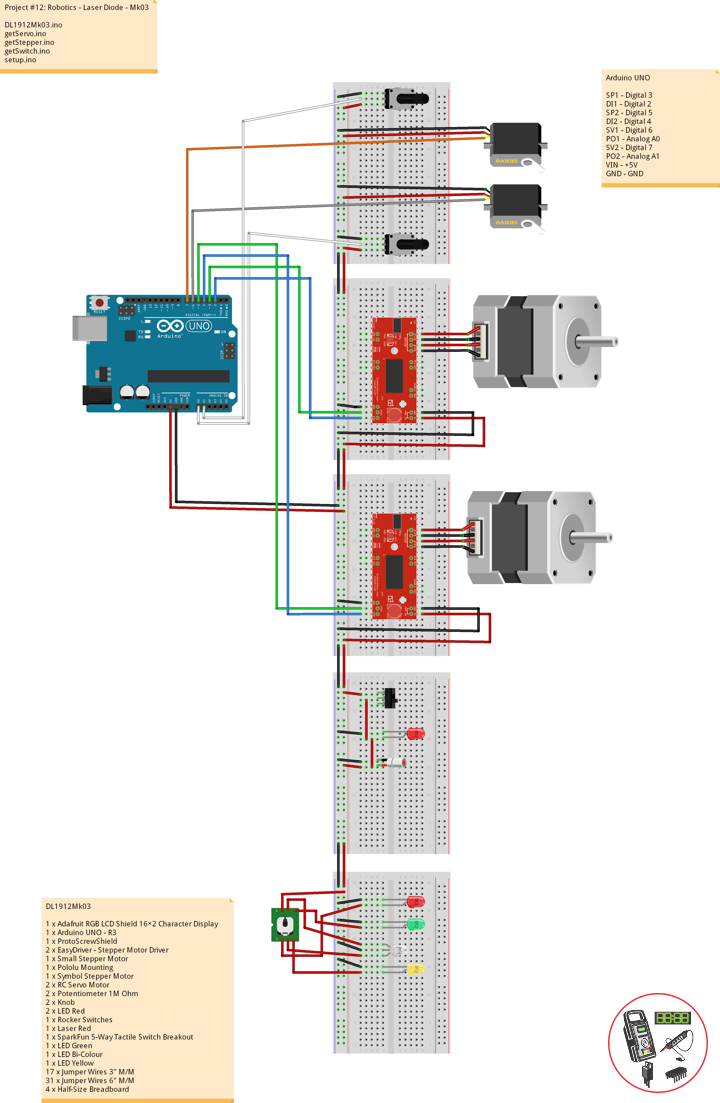

Arduino UNO

TX0 – Digital 1

RX0 – Digital 0

VIN – +5V

GND – GND

XBee S1: Transmitter

CH Channel: C

PAN Id: 3333

SH Serial Number: 13A200

SL Serial Number: 40717A1F

CE Coordinator: Coordinator

BD: 9600

DL2002Mk01p.ino

// ***** Don Luc Electronics © *****

// Software Version Information

// Project #12: Robotics - Unmanned Vehicles 1c - Mk07

// 02-01

// DL2002Mk01p.ino 12-07

// Arduino UNO - R3

// ProtoScrewShield

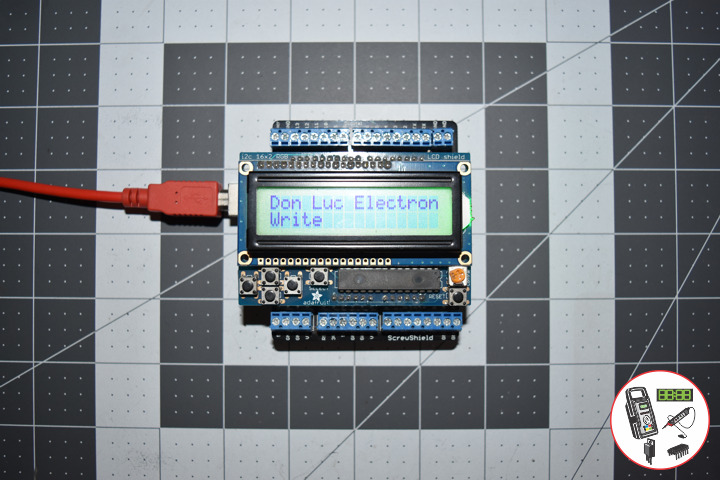

// Adafruit RGB LCD Shield 16×2 Character Display

// EEPROM with Unique ID

// Transmitter

// XBee S1

// Stepper

// Include the library code:

// EEPROM library to read and write EEPROM with unique ID for unit

#include <EEPROM.h>

// Adafruit RGB LCD Shield

#include <Adafruit_RGBLCDShield.h>

// Adafruit RGB LCD Shield

Adafruit_RGBLCDShield RGBLCDShield = Adafruit_RGBLCDShield();

// These #defines make it easy to set the backlight color

#define OFF 0x0

#define RED 0x1

#define YELLOW 0x3

#define GREEN 0x2

#define TEAL 0x6

#define BLUE 0x4

#define VIOLET 0x5

#define WHITE 0x7

// Momentary Button

int yy = 0;

uint8_t momentaryButton = 0;

// Communication

unsigned long dTime = 50;

// The current address in the EEPROM (i.e. which byte we're going to read to next)

// Version

String sver = "12-7.p";

// Unit ID Information

String uid = "";

void loop() {

// Clear

RGBLCDShield.clear();

// set the cursor to column 0, line 0

RGBLCDShield.setCursor(0,0);

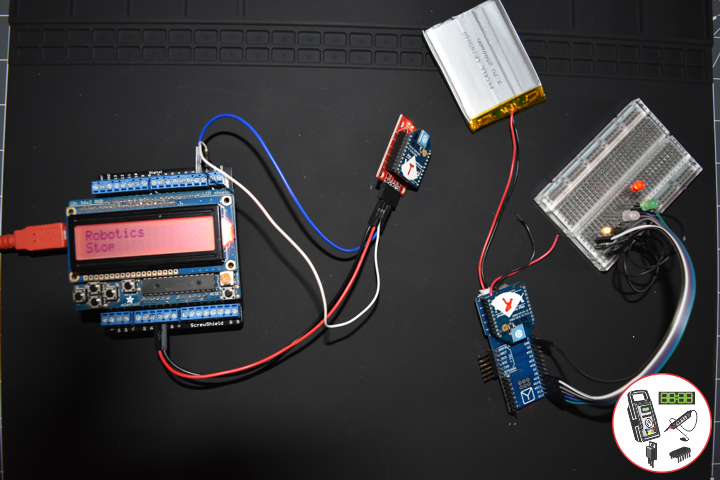

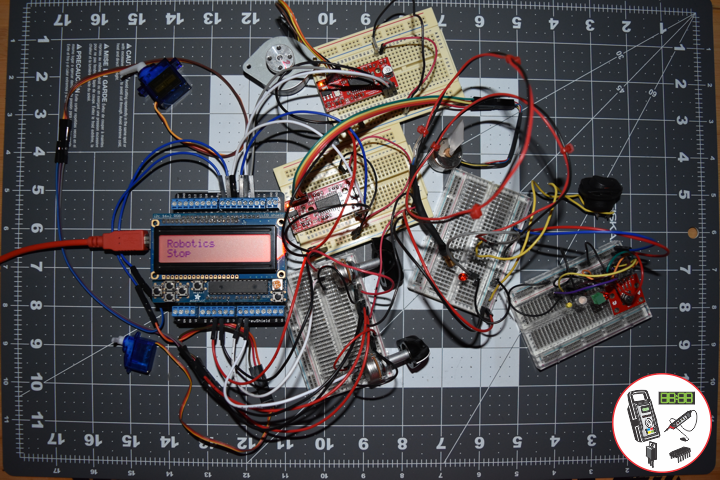

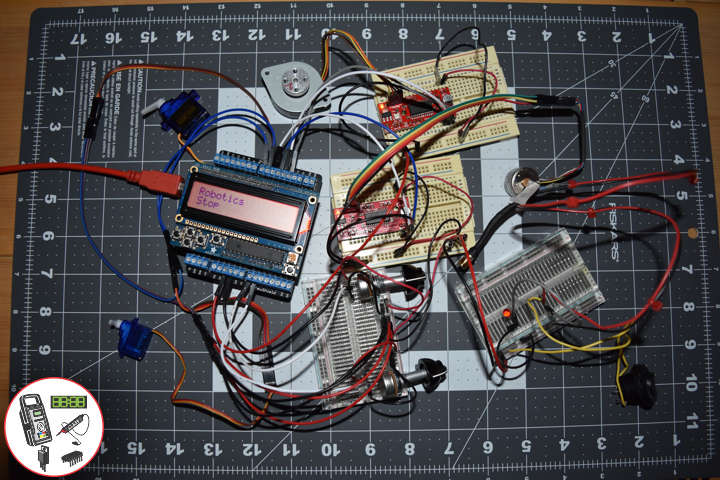

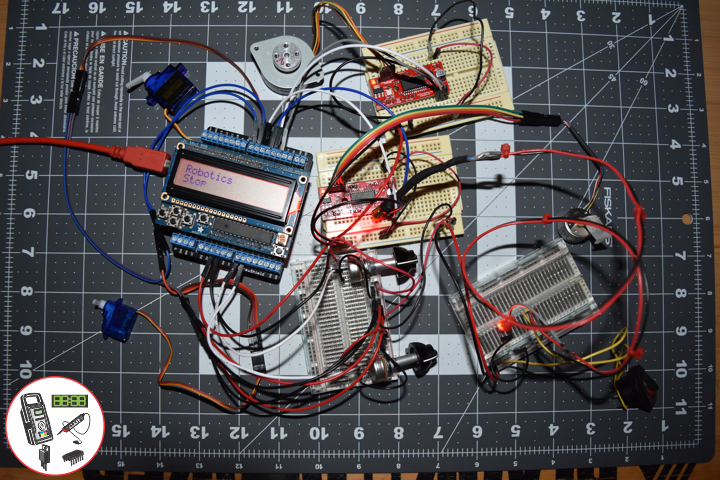

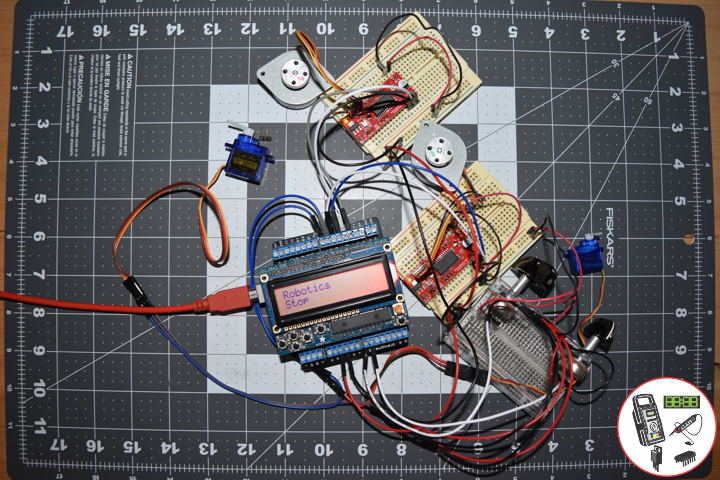

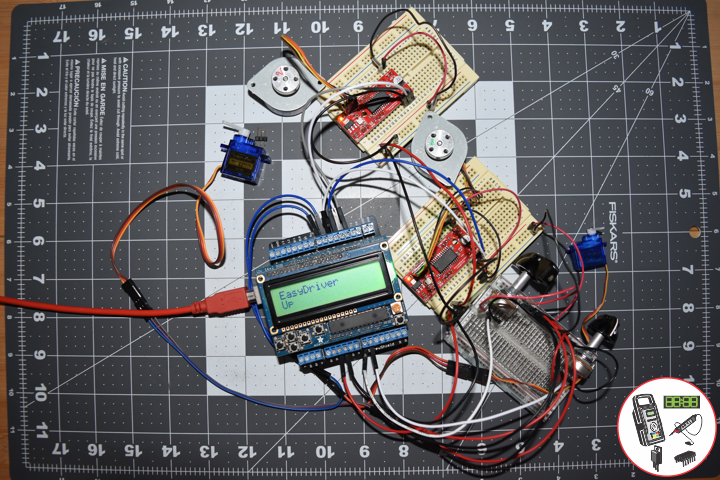

RGBLCDShield.print("Robotics"); // Robotics

// Momentary Button

momentaryButton = RGBLCDShield.readButtons();

switch ( yy ) {

case 1:

// Up

isSwitch1();

break;

case 2:

// Down

isSwitch2();

break;

case 3:

// Right

isSwitch3();

break;

case 4:

// Left

isSwitch4();

break;

case 5:

// Stop

isSwitch5();

break;

default:

// Stop

yy = 5;

RGBLCDShield.setBacklight(RED);

isSwitch5();

}

if ( momentaryButton ) {

if ( momentaryButton & BUTTON_UP ) {

yy = 1;

// Up

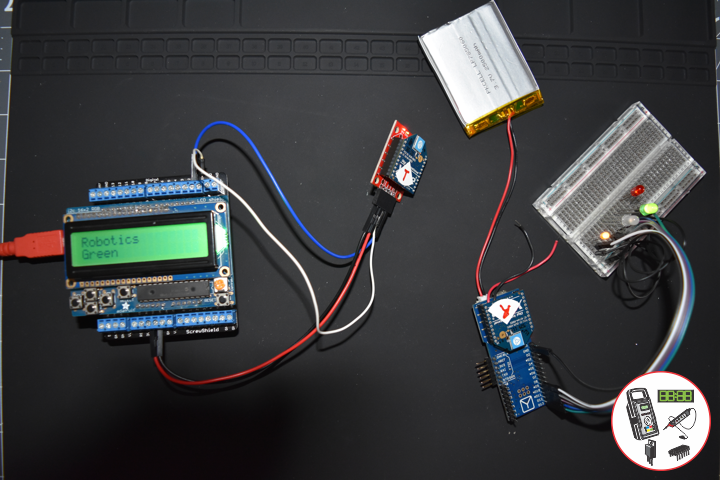

RGBLCDShield.setBacklight(GREEN);

}

if ( momentaryButton & BUTTON_DOWN ) {

yy = 2;

// Down

RGBLCDShield.setBacklight(VIOLET);

}

if ( momentaryButton & BUTTON_LEFT ) {

yy = 3;

// Right

RGBLCDShield.setBacklight(TEAL);

}

if ( momentaryButton & BUTTON_RIGHT ) {

yy = 4;

// Left

RGBLCDShield.setBacklight(YELLOW);

}

if ( momentaryButton & BUTTON_SELECT ) {

yy = 5;

// Stop

RGBLCDShield.setBacklight(RED);

}

}

// Process Message

isProcessMessage();

delay( dTime );

}

getEEPROM.ino

// EEPROM

// isUID

void isUID()

{

// Is Unit ID

uid = "";

for (int x = 0; x < 5; x++)

{

uid = uid + char(EEPROM.read(x));

}

}

getProcessMessage.ino

// ProcessMessage

// isProcessMessage

void isProcessMessage() {

// String msg = "";

/// Loop through serial buffer one byte at a time until you reach * which will be end of message

//while ( Serial.available() )

// {

// Print => XBEE + Unit ID + Version + *

// msg = "XBEE|" + uid + "|" + sver + "|" + yy + "|*";

Serial.print( '<' );

Serial.print( yy );

Serial.println( '*' );

// }

}

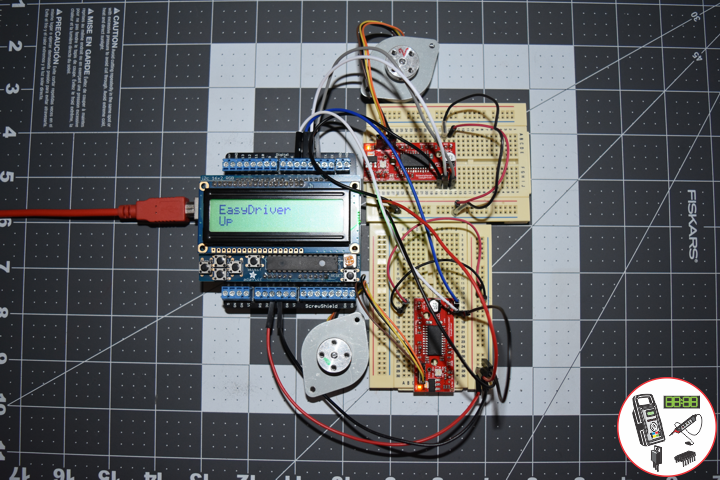

getSwitch.ino

// Switch

// Switch 1

void isSwitch1(){

yy = 1;

// Stepper

// Up

RGBLCDShield.setCursor(0,1);

RGBLCDShield.print("Up");

}

// Switch 2

void isSwitch2(){

yy = 2;

// Stepper

// Down

RGBLCDShield.setCursor(0,1);

RGBLCDShield.print("Down");

}

// Switch 3

void isSwitch3(){

yy = 3;

// Stepper

// Right

RGBLCDShield.setCursor(0,1);

RGBLCDShield.print("Right");

}

// Switch 4

void isSwitch4(){

yy = 4;

// Stepper

// Left

RGBLCDShield.setCursor(0,1);

RGBLCDShield.print("Left");

}

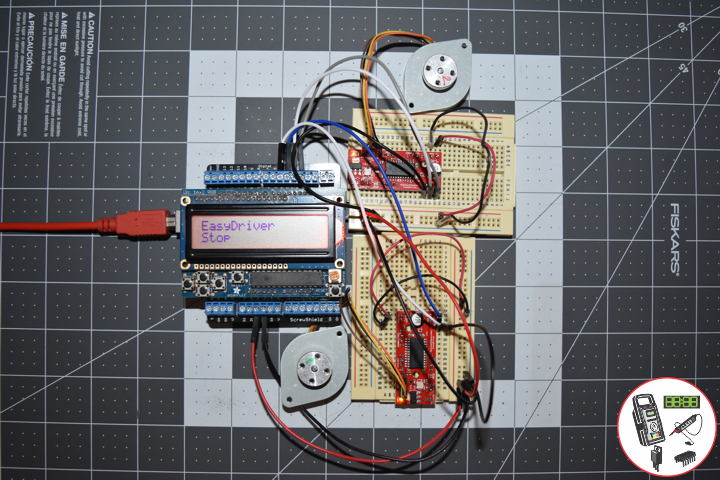

// Switch 5

void isSwitch5(){

yy = 5;

// Stepper

// Stop

RGBLCDShield.setCursor(0,1);

RGBLCDShield.print("Stop");

}

setup.ino

// Setup

void setup() {

// Open serial port at 9600 baud

Serial.begin( 9600 );

// Pause

delay(5);

// EEPROM Unit ID

isUID();

// Pause

delay(5);

// Adafruit RGB LCD Shield

// Set up the LCD's number of columns and rows:

RGBLCDShield.begin(16, 2);

RGBLCDShield.setBacklight(GREEN);

// Display

// Set the cursor to column 0, line 0

RGBLCDShield.setCursor(0,0);

RGBLCDShield.print("Don Luc Electron"); // Don luc Electron

// Set the cursor to column 0, line 1

RGBLCDShield.setCursor(0, 1);

RGBLCDShield.print("Robotics"); // Robotics

// Serial

// Serial.println( "Don Luc Electronics");

// Serial.println( "Robotics");

delay(5000);

// Clear

RGBLCDShield.clear();

// Display

// Set the cursor to column 0, line 0

RGBLCDShield.setCursor(0,0);

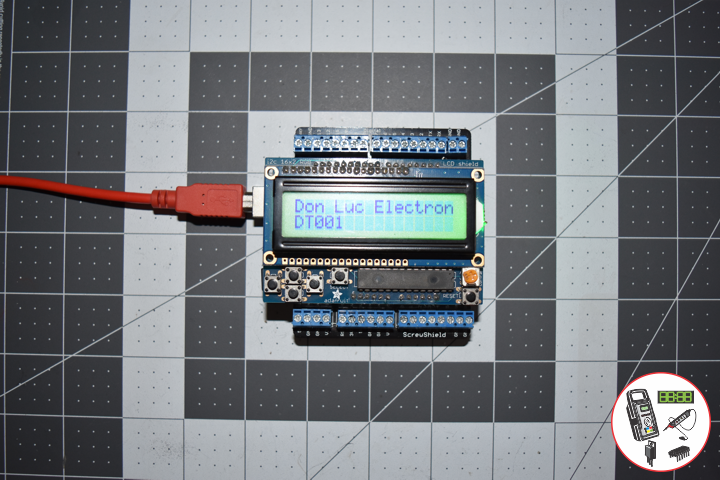

RGBLCDShield.print("Version: "); // Version

RGBLCDShield.print( sver );

// Set the cursor to column 0, line 1

RGBLCDShield.setCursor(0, 1);

RGBLCDShield.print("UID: "); // Unit ID Information

RGBLCDShield.print( uid );

// Serial

// Serial.print( "Software Version Information: ");

// Serial.println( sver );

// Serial.print( "Unit ID Information: ");

// Serial.println( uid );

delay(5000);

// Clear

RGBLCDShield.clear();

}

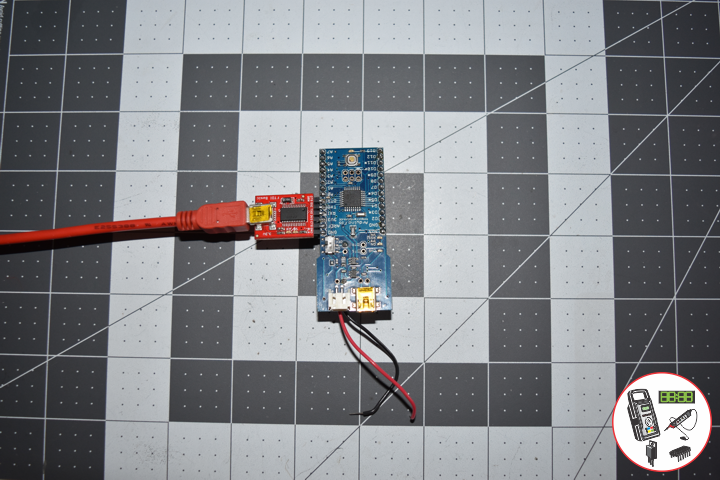

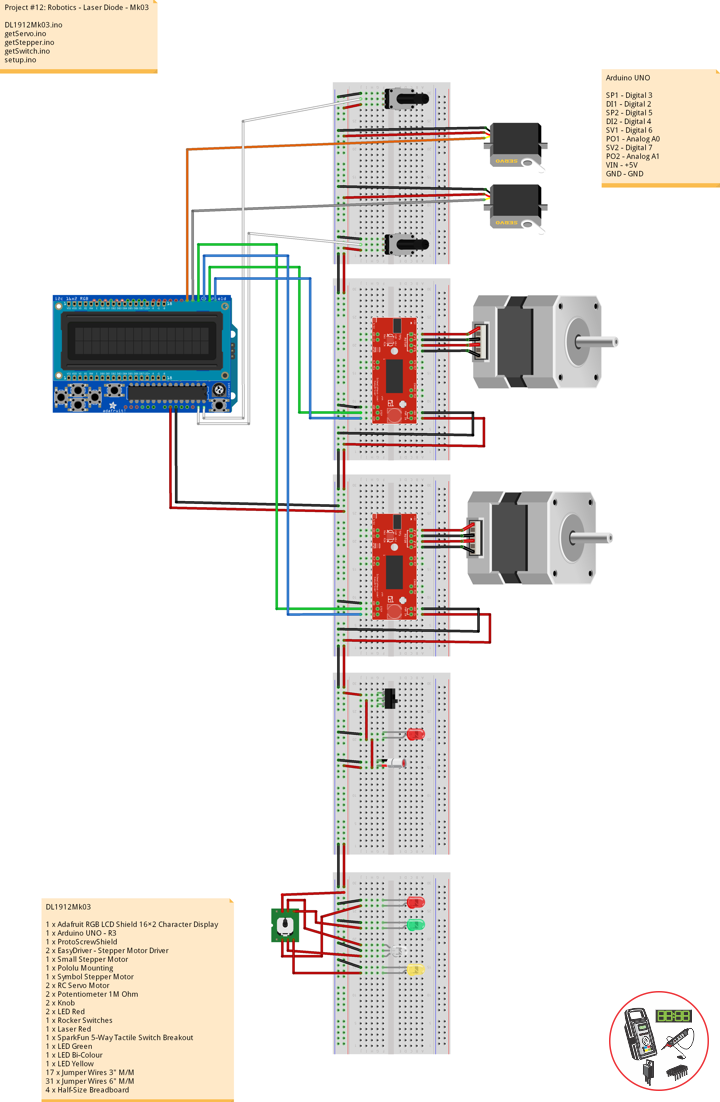

Arduino UNO – SparkFun RedBoard

SP1 – Digital 3

DI1 – Digital 2

SP2 – Digital 5

DI2 – Digital 4

TX0 – Digital 1

RX0 – Digital 0

VIN – +3.3V

GND – GND

XBee S1: Receiver

CH Channel: C

PAN Id: 3333

SH Serial Number: 13A200

SL Serial Number: 4076E2C5

CE Coordinator: End Device

BD: 9600

DL2002Mk01Rp.ino

// ***** Don Luc Electronics © *****

// Software Version Information

// Project #12: Robotics - Unmanned Vehicles 1c - Mk07

// 02-01

// DL2002Mk01Rp.ino 12-07

// Arduino UNO - SparkFun RedBoard

// EEPROM with Unique ID

// Receiver

// Breakout Board for XBee Module

// XBee S1

// 2 x EasyDriver

// 2 x Small Stepper

// Include the library code:

// EEPROM library to read and write EEPROM with unique ID for unit

#include <EEPROM.h>

// Momentary Button

int yy = "";

// 2 x EasyDriver - 2 x Stepper

int dirPinR = 2; // EasyDriver Right

int stepPinR = 3; // stepPin Right

int dirPinL = 4; // EasyDriver Left

int stepPinL = 5; // stepPin Left

int i = 0;

// Software Version Information

String sver = "12-07";

// Unit ID information

String uid = "";

void loop() {

// Check for serial messages

if ( Serial.available() )

{

isProcessMessage();

}

// Switch

isSwitch();

}

getEEPROM.ino

// EEPROM

// isUID

void isUID()

{

// Is Unit ID

uid = "";

for (int x = 0; x < 5; x++)

{

uid = uid + char(EEPROM.read(x));

}

}

getProcessMessage.ino

// ProcessMessage

// isProcessMessage

void isProcessMessage() {

int incb = 0;

String msg = "";

String zzz = "";

// Loop through serial buffer one byte at a time until you reach * which will be end of message

while ( Serial.available() )

{

// Read the incoming byte:

incb = Serial.read();

// Add character to string

msg = msg + char(incb);

// Check if receive character is the end of message *

if ( incb == 42 )

{

// Serial.println(msg);

zzz = msg.charAt( 1 );

// Serial.println(zzz);

yy = zzz.toInt();

// Serial.println( yy );

}

}

}

getStepper.ino

// Stepper

// isStepperSetup

void isStepperSetup() {

// 2 x EasyDriver

pinMode(dirPinR, OUTPUT);

pinMode(stepPinR, OUTPUT);

pinMode(dirPinL, OUTPUT);

pinMode(stepPinL, OUTPUT);

}

// isStepper1

void isStepper1(){

// 2 x EasyDriver - Up

digitalWrite(dirPinR, LOW); // Set the direction.

delay(5);

digitalWrite(dirPinL, LOW); // Set the direction.

delay(5);

for (i = 0; i<300; i++) // Iterate for 1000 microsteps.

{

digitalWrite(stepPinR, LOW); // This LOW to HIGH change is what creates the

digitalWrite(stepPinR, HIGH); // "Rising Edge" so the easydriver knows to when to step.

delayMicroseconds(300); // This delay time is close to top speed.

digitalWrite(stepPinL, LOW); // This LOW to HIGH change is what creates the

digitalWrite(stepPinL, HIGH); // "Rising Edge" so the easydriver knows to when to step.

delayMicroseconds(300); // This delay time is close to top speed.

}

}

// isStepper2

void isStepper2(){

// 2 x EasyDriver

digitalWrite(dirPinR, HIGH); // Set the direction.

delay(5);

digitalWrite(dirPinL, HIGH); // Set the direction.

delay(5);

for (i = 0; i<1000; i++) // Iterate for 1000 microsteps.

{

digitalWrite(stepPinR, LOW); // This LOW to HIGH change is what creates the

digitalWrite(stepPinR, HIGH); // "Rising Edge" so the easydriver knows to when to step.

delayMicroseconds(300); // This delay time is close to top speed.

digitalWrite(stepPinL, LOW); // This LOW to HIGH change is what creates the

digitalWrite(stepPinL, HIGH); // "Rising Edge" so the easydriver knows to when to step.

delayMicroseconds(300); // This delay time is close to top speed.

}

}

// Switch 3

void isStepper3(){

// Right

// 2 x EasyDriver

digitalWrite(dirPinR, LOW); // Set the direction.

delay(5);

digitalWrite(dirPinL, HIGH); // Set the direction.

delay(5);

for (i = 0; i<300; i++) // Iterate for 1000 microsteps.

{

digitalWrite(stepPinR, LOW); // This LOW to HIGH change is what creates the

digitalWrite(stepPinR, HIGH); // "Rising Edge" so the easydriver knows to when to step.

delayMicroseconds(300); // This delay time is close to top speed.

digitalWrite(stepPinL, LOW); // This LOW to HIGH change is what creates the

digitalWrite(stepPinL, HIGH); // "Rising Edge" so the easydriver knows to when to step.

delayMicroseconds(300); // This delay time is close to top speed.

}

}

// Switch 4

void isStepper4(){

// Left

// 2 x EasyDriver

digitalWrite(dirPinR, HIGH); // Set the direction.

delay(5);

digitalWrite(dirPinL, LOW); // Set the direction.

delay(5);

for (i = 0; i<300; i++) // Iterate for 1000 microsteps.

{

digitalWrite(stepPinR, LOW); // This LOW to HIGH change is what creates the

digitalWrite(stepPinR, HIGH); // "Rising Edge" so the easydriver knows to when to step.

delayMicroseconds(300); // This delay time is close to top speed.

digitalWrite(stepPinL, LOW); // This LOW to HIGH change is what creates the

digitalWrite(stepPinL, HIGH); // "Rising Edge" so the easydriver knows to when to step.

delayMicroseconds(300); // This delay time is close to top speed.

}

}

// isStepperStop

void isStepperStop() {

// 2 x EasyDriver

digitalWrite(dirPinR, LOW); // Set the direction.

delay(5);

digitalWrite(dirPinL, LOW); // Set the direction.

delay(5);

digitalWrite(stepPinR, LOW); // This LOW to HIGH change is what creates the

digitalWrite(stepPinL, LOW); // This LOW to HIGH change is what creates the

}

getSwitch.ino

// Switch

// isSwitch

void isSwitch(){

switch ( yy ) {

case 1:

// Stepper 1 - Up

isStepper1();

break;

case 2:

// Stepper 2 - Back

isStepper2();

break;

case 3:

// Stepper 3 - Right

isStepper3();

break;

case 4:

// Stepper 4 - Left

isStepper4();

break;

case 5:

// Stepper Stop

isStepperStop();

break;

default:

// Stepper Stop

isStepperStop();

}

}

setup.ino

// Setup

void setup() {

// Open the serial port at 9600 bps:

Serial.begin( 9600 );

// Pause

delay(5);

// EEPROM Unit ID

isUID();

// Pause

delay(5);

// Serial

// Serial.print( "Software Version Information: ");

// Serial.println( sver );

// Serial.print( "Unit ID Information: ");

// Serial.println( uid );

// delay(5000);

// 2 x EasyDriver

isStepperSetup();

}

Follow Us

J. Luc Paquin – Curriculum Vitae

https://www.donluc.com/DLHackster/LucPaquinCVEngMk2020a.pdf

Web: https://www.donluc.com/

Web: http://www.jlpconsultants.com/

Web: https://www.donluc.com/DLHackster/

Web: https://www.hackster.io/neosteam-labs

Web: http://neosteamlabs.com/

YouTube: https://www.youtube.com/channel/UC5eRjrGn1CqkkGfZy0jxEdA

Facebook: https://www.facebook.com/neosteam.labs.9/

Instagram: https://www.instagram.com/neosteamlabs/

Pinterest: https://www.pinterest.com/NeoSteamLabs/

Twitter: https://twitter.com/labs_steam

Etsy: https://www.etsy.com/shop/NeoSteamLabs

Don Luc